9 Teck Coal – Greenhills

This Moose Mountain employee adds considerable value to the Greenhills mine with her local knowledge and geologic expertise

By | February 25, 2020

/

Click to zoom.

Local talent shines through in Jaclyn Galbraith’s work at Teck Coal

This Moose Mountain employee adds considerable value to the Greenhills mine with her local knowledge and geologic expertise

Byline: Virginia Rasch

Jaclyn Galbraith is on location at one of Foraco’s reverse circulation drill rigs in the exploration program at Greenhills mine.

Jaclyn Galbraith scouts locations prior to pad construction for the in-pit program at the Greenhills mine.

Photo credits: Photos courtesy Teck Coal

Although Jaclyn Galbraith works for Moose Mountain, her expertise lies in mountains and mountains of coal.For the last year and a half, Galbraith has been a geological consultant to Teck Coal at its Greenhills mine in the Elk Valley of southeastern British Columbia.

She is a Geological Engineer in Training with Moose Mountain Technical Services, based out of Cranbrook, B.C., for the past eight years. The company offers a full range of mining expertise from exploration to operation.

Galbraith works in the absolute core of the Canadian metallurgical coal industry, and coal cores are her bread and butter.

She has worked on a variety of projects at the Greenhills mine, ranging from desktop studies to fieldwork on sampling and drilling programs. In all of these projects, her attention to detail, organizational skills and expertise assisted Teck staff in increasing the efficiency of its mining operations by finding the coal seams with the best coking properties.

In-pit projects at the Greenhills mine

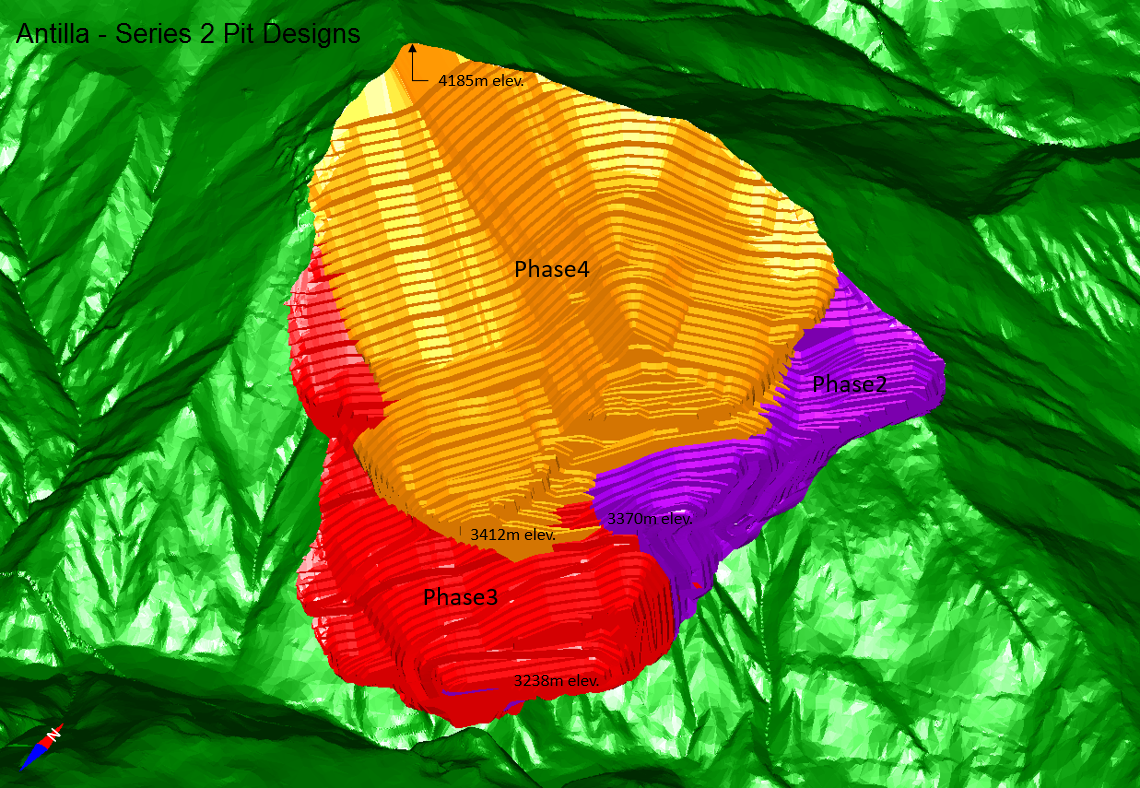

In the summer of 2017, Galbraith conducted an in-depth study of the geology at the north end of the site. “My work involved reviewing recent and historic geophysical logs to confirm correlation and updating the geological interpretation in MineSight 3D (a leading mine planning software program),” Galbraith said.

In another project, she led an extensive sampling program of coal seams in a newer pit. Working in the pit, she collected samples from the raw coal piles to test the ash content. Samples were shipped to a laboratory, and Galbraith assessed the results to provide the information needed to calibrate the ash probe tool.

Beginning in the spring of 2018, Galbraith assisted in managing three exploration drill programs at Greenhills. The purpose of the drill programs was to gather information about the location and quality of the coal seams that will be mined in the coming years.

Much teamwork is needed to run an in-pit drill program with 40 drill holes and one drill rig running 24 hours a day alongside active shovels, haul trucks, and other heavy equipment. The geologists included Galbraith, the Greenhills geology group and additional Teck geologists from other locations.

“We co-ordinated with the mine operations crews and the contract drill crews to run the program,” said Galbraith. “Planning and co-ordinating the drill locations around active mine operations and equipment was a new experience for me, and I enjoyed the challenge.”

Galbraith’s tasks included organizing the construction of the new drill pads, daily safety reviews and sampling plans. She also worked with the biologist who conducted environmental surveys for breeding birds.

On the ground, work entailed tracking coal intersections and determining when each drill hole had reached the target depth.

Collecting not just the drill samples but all the metrics is critical to the success of the drill program. Galbraith co-ordinated with the laboratory for proper testing and analyses, and worked with the geophysical logging contractors to ensure all required analyses were run on the drill holes.

Geophysical data was entered into the database so the 3-D geological interpretation could be updated for modelling and planning purposes. The end goal is to improve the confidence of the geological interpretation and coal quality properties to increase efficiency in the mining process.

Exploration drill programs

Galbraith then moved on to assist in managing two exploration drill programs outside of the active pits, in areas that will be mined in the future. Two drills were running 24 hours a day, with one exploration area having 40 holes and another with 23 holes. Some of the time, there was a third drill working to obtain bulk samples of specific coal seams of interest.

With about 15 people on the project site each day, is imperative. Teck built the team with its local and regional staff as well as contractors, including Galbraith of Moose Mountain as well as Foraco Canada, Kettle River Contracting, Silenus Resource Management, Transcendent Mining and Mobilization, Guardian First Aid Service and Anatum Ecological Consulting.

For example, effective communication was required between the field supervisor, equipment operators and drill crews to make sure construction stayed ahead of drilling.

“The drilling here was to increase the amount of information in the area and will go towards the pit shell design,” said Galbraith.

These areas are in the earlier planning stages so the collected geological data are crucial for future success. Galbraith worked extensively with the safety groups to ensure that all safety requirements were being followed during drilling and road and pad construction. She also conducted field mapping and surveying of new road cuts as access was built to new drilling locations.

“Other tasks that were carried out included daily cost tracking and reporting on the progress of the program to senior personnel,” Galbraith said. “Once this drill program was completed, I reviewed the correlation and updated the geological interpretation for the area, which is now being incorporated into the model.”

Her future plans at Greenhills

She plans to continue as a consultant with Teck Coal’s Greenhills mine. Her value to the operations include her strong geology background, her knowledge of the local area and her years of experience working on a variety of coal projects in the region.

In her work, Galbraith enjoys the diversity of tasks and the teamwork that leads to success.

“I really enjoy seeing how each project fits in differently to the planning and operation of the mine,” Galbraith said. “I worked with a variety of people with different backgrounds and expertise. It’s a great opportunity to collaborate and learn from other people within the operation and to see how all of those pieces are put together.”

Galbraith also feels fortunate to work with several other women at Greenhills in an occupation typically dominated by men.

Galbraith and Moose Mountain Technical Services appreciate the relationship they have built with Teck over the years and the opportunity to work in their own backyards .

Other Projects: